Steve

Bedair's

Telescope Site

Longview , Texas

Updated 2-2003

Celestron C-11 LXD Powered

Mount

Az / Alt Bearing Supports

Az Bearing Support

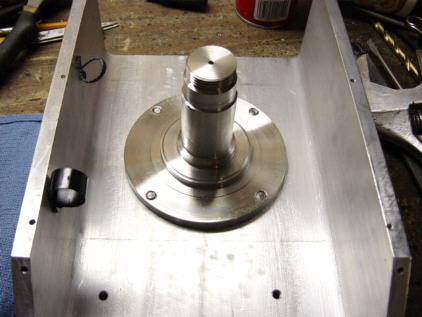

Az bearing and worm gear assembly for the C-11 mount.

Here's what I came up with for the Az bearing support for the C-11 mount.

It's design was

the result of the bearings I was able to find on E-Bay. It uses a large

4.5" OD x 2 7/8" Id

roller bearing in the bottom and a smaller 2.5" OD x 1 3/4" in the

top of the bearing cage.

I did all the lathe work on my Harbor Freight

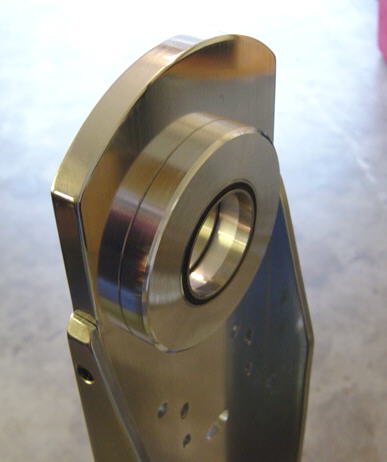

9x metal lathe. The brass fingers are the clutching

mechanism which apply equal pressure to the top of the 200 tooth aluminum

worm gear by a

threaded stud.

Az bearing assembly parts

The brass clutching "fingers" are threaded into a steel ring.

The brass fingers apply pressure to 3 equal places on a stainless steel

ring that applies pressure to the worm gear. When the clutching bolt

is

loosened the fork assembly can be turned easily. When the clutching

bolt is tightened the worm gear is sandwiched between two stainless

steel plates.( A lot of work but it really works well )

Az 200 tooth worm gear bored to fit around the OD of the bearing holder.

The Az shaft bolts directly to the bottom of the mount case.

This provides a very solid mount for the fork assembly.

ALT Bearing Supports

The Alt axis uses two thin 2 7/8" ID precision roller bearing for each

fork.

The bearings are pressed into an aluminum bearing holder. The bearing

holder is then bolted to the fork arm.

Thin roller bearings from E-Bay.

The Alt shafts are stainless steel and these stay attached to the mount

at

all times , even when the ota is removed. The center hole is for attaching

the ota.

The same for the worm gear side. The worm gear stays tightened to the

alt

shaft at all times. The hole through the center acts as the clutch

and attaching

bolt. With this method it's possible to keep the worm and worm

gear meshing

perfectly since it is left tightened in place at all times.

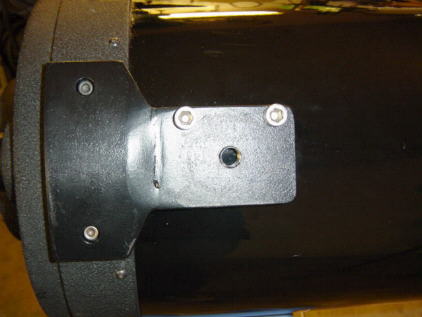

The stainless steel alt shafts protrude 1" toward the ota. The ota has

homemade steel

brackets that attach to the ota & sit on the shafts. The ota brackets

are threaded

for the attaching bolts. This makes it super easy to remove or place

the ota on the mount.

The steel brackets stay attached to the OTA. The two allen head bolts

on the right side act as stops when the ota is placed on the mount.

They

also place the ota in perfect alignment while the attaching bolts are

tightened.

Comments / Questions /

Suggestions or Add Your Link

This information is provided for personal use only.

I cannot be responsible for any joy this may bring.

Copyright 2001-2002-2003

Steve Bedair