Steve

Bedair's

9 x 20 Lathe Site

Longview , Texas

6 -2002

Indexable Turning Tools

How to build your own

The building pics below show attaching 1/4" TCMT carbide inserts to

1/2 tools.

This method will work for a range of different sizes.

First the insert is laid out on the

1/2" square steel

A protractor and a metal scribe to make marks.

I make most of my tool holders 4" long.

Be sure to position the insert as shown.

You do not

want the tip to hang over the edge of

the steel.

This supports the carbide cutting tip.

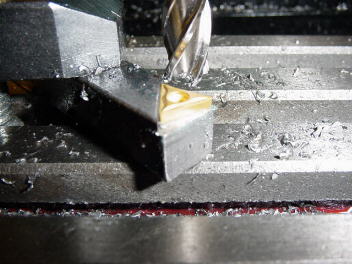

Using the Mini Mill I mill the recess for the insert.

Milling completed

If you don't have a mill you could use a lathe with a

milling attachment.

Slightly file the top edge

of the 1/2" steel as shown

Using a metal scribe while pressing the insert firmly against

to allow for the bevel of

the insert. You don't have to the edge

of my workbench I mark the center hole location.

remove much metal and it

does not have to match

the bevel exactly.

The blue represents the scribe mark. I use a center punch to mark the

screw hole location.

If you look closely you will notice the punch mark is slightly toward

the filed edge of the tool.

This ensures that the insert fits tight against

the back filed edge of the tool holder.

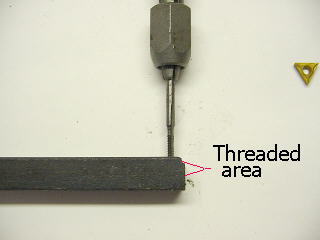

I have already drilled a # 43 hole to allow for the 4-40 tap.

I next use a 17/64" and drill approx 1/16" deep. This prevents

any pulled threads from interfering with the insert.

Before tapping I also drill from the bottom

of the tool holder I used 4-40

allenhead screws to attach the inserts to

approx half way using the larger 7/64" drill

bit. You do not the

1/2" tools. I had to cut bevels on the screws as

want to cut threads the full thickness of

the 1/2" tool. You

shown below.

will never make it the full thickness with

such a small tap.

Tap slow and use lots of oil. ( I broke my

first tap )

Click here for a detailed picture

Using my 9 x 20

lathe I beveled the 4-40 allenhead screws.

Go slow and easy.

4-40 allenhead screw

before and after bevel is cut

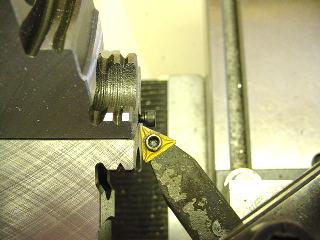

Attach the insert and scribe the sides of the insert.

Shows where metal will need to be removed.

Using a 1/4" inserts on a 1/2" tool I also scribed a

line to remove metal from the right side of the tool

Using an end mill I removed metal to the scribe mark.

Using a fine grit grinding wheel remove excess metal.

Keep the tool quenched regularly and you will be able

to see the scribe mark.

Grinding the edges is complete

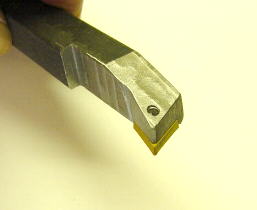

I also milled an angle on the bottom side of the tool

Be careful not to remove too much material

from the tip. You want the carbide cutting tip

to be supported.

Completed tool !!

I have posted

this information to help provide an alternative for building less expensive

lathe turning tools.

I am not saying this is the best way to do it , it's

just the way I did it.

Comments / Questions /

Suggestions or Add Your Link

This information is provided for personal use only

I cannot be responsible for any $$ this may save.

Copyright 2002 Steve Bedair