Steve

Bedair's

9 x 20 Lathe Site

Longview , Texas

10 -2002

Crossfeed Lead Screw Mount

Harbor Freight 9 x 20 Lathe

I had originally planned on building the mount from aluminum but after

a trip to the local

metal salvage yard I decided on stainless steel. ( Aluminum would work

fine )

The extra length of the new mount is to allow for the thickness of

the ball bearing used

on the handle end and plus another 3/4" for extra travel.

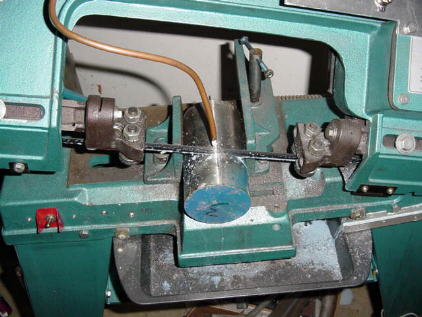

I first cut the 3" OD stainless to length

on my 4x6 bandsaw

Before & after

This took awhile !

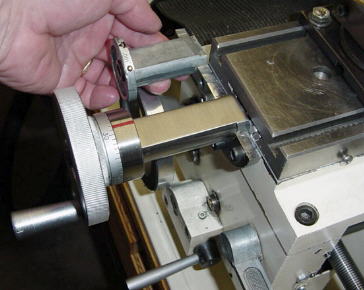

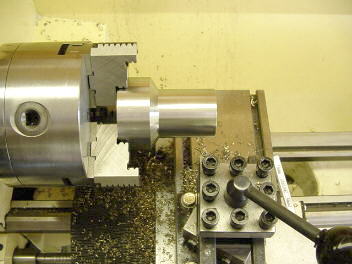

I started work on the handle end of the mount

I bored the ID to accept the ball bearing

Finished turning the handle end.

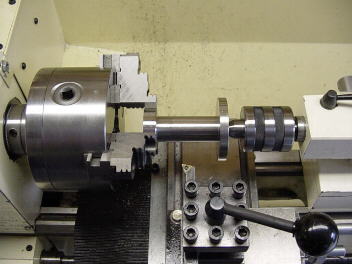

Turned it around and turned the mounting flange.

Using the Mini Mill and a 1/2" end mill I slowly removed

the excess metal.

I also added an extra attaching bolt to the bottom of the new mount.

Good Luck,

Steve

Comments / Questions /

Suggestions or Add Your Link

This information is provided for personal use only

Copyright 2002 Steve Bedair