Steve

Bedair's

9 x 20 Lathe Site

Longview , Texas

6 -2002

Building a chuck back plate for

the HF 9 x 20

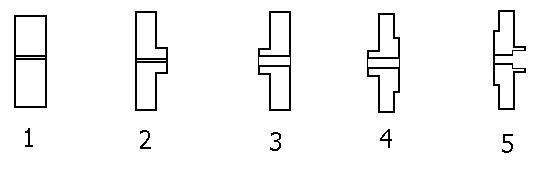

I'm no artist but here are the turning steps I used building my back plate.

In each drawing the back plate is held

in the chuck from the left side or just as you

would face the lathe. I would strongly recommend purchasing

a cast iron blank back plate and save yourself

a lot of work.

This describes the method I used to build my

back plate, I'm not saying it's the best way

it's just the way I did it.

1.

Drilled a 3/4" hole through the center of the blank. Attached blank

to lathe using a 3/4" bolt held in the chuck.

2.

Formed the back side of the back plate using measurements from the original

4" back plate.

3.

Removed the 3/4" bolt and turned the back plate around. Attach the back

plate using the shoulder that was cut

in pic # 2. Bore the ID of the back plate to match the OD of the

spindle thread root. Be careful and remember

this is the ID where the threads will be formed. For mine the hole

was bored to 1.316"

4.

Created a shoulder wide enough for the chuck jaws to clamp to so the back

plate can be turned around.

5.

Turn the back plate around and clamp to the shoulder created in pic # 4.

Measure closely and bore

the ID of the back pate to allow for the shoulder of the spindle to fit

correctly. The remaining material

will allow for the threads to be formed.

After

pic # 5 I cut the 4mm ID threads from the backside of the back

plate. In other words the threading tool

will

enter from the back of the back plate. This is where the spindle

test piece is needed. Keep cutting threads

until

the test piece fits. Once the threads are complete the original chuck can

be removed from the lathe and the

newly

completed back plate can be attached to the spindle. Once the new back

plate is attached the face of

the

plate can be cut to match the chuck. The OD of the back plate can also

be cut to match the OD of the new chuck.

And

last but not least you will need to drill the mounting holes through the

back plate , I used a dividing head to

space

the holes evenly you can however do some creative measuring and make it

work.

Spindle test piece cut from aluminum

How to cut 4 mm threads

Jeff Davis's Back Plate

Comments / Questions /

Suggestions or Add Your Link

This information is provided for personal use only

Copyright 2002 Steve Bedair